Selecta Systems Technical Manager Cliff Prosser and Marketing Manager Mark Walker, look in to the details regarding the recent building regulation changes to Part L and the marketing opportunities that this brings to fabricators and installers.

The technical performance and specification of window and door systems has evolved dramatically over the last few years, as window and door solutions have developed on the back of media pressure in regards to climate control. The introduction of greater industry statutory and regulatory requirements, combined with consumer demand in relation to the ever-increasing costs of energy supply, have been defining factors in driving window and door system innovation and design. With the recent and future changes to Part L, coupled with further calls for action on climate control and sustainability, pressure remains on further product energy efficiency innovation and sustainability.

Cliff comments, “These changes to Part L of the building regulations have seen Selecta provide further investment in our research and development programme. Our existing five chambered ADVANCE 70 system already meets the 1.2W/m²k U value requirements with either 24mm or 28mm double glazing and 1.0W/m²k with a 40mm triple glazed unit. Our R&D programme is looking at product, ancillary and glazing solutions and capabilities to improve this further.”

“For instance, I have recently completed a training course to become a WER / U Value approved simulator, one of only around 40 in the country. Selecta are able to provide a comprehensive technical, WER and U Value support service to our customer base, whilst enabling us to accelerate the energy efficiency product development and innovation process.”

“This in-turn supports us further in working towards the proposed 2025 Document L changes as we invest more resources in to developing our range of window and door solutions. The final intended 0.8 U value requirement will pose a challenge for many in our industry. With these planned tighter regulations, this may mean that some products on the market may have already or be close to reaching their design limits as companies look at future proofing their product range. However, our company ethos will remain the same. Any new developments and enhancements shall continue to be fabricator and installer friendly, whilst also being as cost effective as is possible.” says Cliff.

These recent and future changes to Part L paired with the ever-increasing cost of energy, do nevertheless provide fabricators and installers with a marketing opportunity, as Mark explains.

“At the moment we have an ever-growing problem. Rising energy costs. With many looking at ways of reducing their energy consumption and improving their homes energy efficiency levels, we have a range of products that provide a long-term solution to their problem – increasing their necessity to the consumer. Windows and doors are often seen as a ‘distress purchase’. A purchase made out of necessity rather than pleasure.”

“When you consider that replacing windows and doors within a home is amongst one of the largest investment renovations that a consumer will undertake on their property, energy efficiency will now very likely feature top of their requirements when choosing replacement windows and doors, closely followed by security and aesthetics.”

“What this means is that window and door companies have the ideal opportunity to promote the energy efficiency of their products as one of the main USP’s. Replacing ageing and tired windows and doors with new are a necessity to improve their homes thermal efficiency and reduce their energy bills. The latest and future revisions to Part L also provides companies with a legislative platform for promoting the thermal performance of windows and doors within the home.” Mark concludes, “Having touched on the regulation changes and marketing opportunities, it’s vitally important that fabricators and installers partner with the right window and door system and supplier. One that can provide future proofed window and door solutions. One that is looking at long-term innovation and development of its products and services. One that can provide that range of support tools and services. Selecta are that window and door system supplier and the ADVANCE 70 System is that window and door profile system.”

Over the course of the last five issues, we’ve provided you with a ‘Behind the Scenes’ insight in to PVCu window and door systems company Selecta Systems. In our final behind the scenes feature, Sales Director Andy Green takes us through some key staff and areas within the business, ones that continue to provide an invaluable and vital service to the business and customers.

In our previous features we’ve looked at many aspects of Selecta, the PVCu window and door systems extrusion and production inner workings, servicing and support mechanisms. We started with the mixing plant and extrusion process, going from powder to plastic and that it’s not just a piece of plastic, but a precision engineered product.

The second instalment saw us talk about the rigors and brutality of PAS 24 testing and the ruthless process windows and doors undergo to gain certification for enhanced security performance. This was followed by the fascination of lamination, a very insightful look in to how colour has changed the market and the process behind turning your standard plastic base colours in to both modern and traditional on-trend shades and grained effects.

We’ve also looked at the marketing support area and how Selecta supports their growing loyal customer base, as well as newly converted customers. This led to technical support and the transition process of converting customers to Selecta and the personal technical support package that this provided.

These previous five ‘Behind the Scenes’ features have provided you with an in depth understanding of the workings and complexities of an extrusion company, from providing fabricators with a piece of plastic to supporting the customer during their journey with the business. But it doesn’t stop there and so we look at some of the team behind the scenes…

As Sales Director, the customer facing sales development team report to myself, where I’m responsible for looking after the growth of existing and new business, providing support from within the office and face-to-face. With over 32 years of service at Selecta I have held a number of roles with different responsibilities.

I originally started life at Selecta as a field sales representative before moving into the technical department. After becoming the technical manager, I was then appointed UK business manager, before finally being promoted to my current role as sales director in 2016.

In fact, I was already part of the ‘family’ before I joined Selecta, as I was a customer with Adapta Windows. Indeed, Adapta was also a family run business, which was owned by my father and so there has always been this strong family connection with myself.

Out on the road, we have three Sales Representatives / Business Development Managers, who have their dedicated postcode areas across the country. Dave Nelson, who previously worked for a customer of Selecta, has been with us since 2016 and has a very comprehensive range of fabrication knowledge and experience of our ADVANCE 70 System. A popular character amongst our customers, Dave mainly covers the London, Midlands and North West.

Richard Reeves joined Selecta in 2018 from a window and door machinery and consumables supplier, again bringing a wealth of knowledge of customers and the industry to Selecta. Covering mainly Wales, Midlands and eastern side of the UK.

New to the business is Matt Blake, who joined the Selecta family in the middle of this year. Matt has previous experience within the industry and a background in sales. Matt not only covers Scotland and the North East, but also the South West and South Coast.

Sales and accounts are managed by Maria Lawrence, who is one of the longest serving member of the team. Upon joining Selecta, Maria was one of only 7 or 8 employees at the time and has worked her way up from an Order Processor and Accounts Manager to her current role.

Long serving employees Marie Astley and Gayle Stephens co-ordinate, manage and process all customer orders, with Credit Control Manager Lorraine Hammond, supported by Maureen Taylor, managing customers’ accounts. Marie, Gayle and Lorraine all have 22+ years’ service each, gaining a wealth of experience and knowledge of the business and our customers during this time.

Transport and warehouse logistics are managed by Lee Davey. Lee is in his second spell at Selecta, after finding out that the grass wasn’t greener on the other side! In the eleven years since his return to the business Lee has managed the trade counter and worked within purchasing, stock control, transport and logistics. He was recently appointed Warehouse & Logistics Manager and has already had a big influence on the development of the department.

Lee’s role sees him coordinating and managing all processes relating to customer order picking, packing and delivery. Customer orders are meticulously picked and packed by the warehouse team, ready for despatch across the length and breadth of the UK.

Management of the delivery vehicles and drivers is also undertaken by Lee. Selecta own their own fleet of trucks and delivery vehicles, which operate on a daily basis. An in-house garage and repair shop maintains the delivery fleet, ensuring that they remain in tip-top condition, serving our customers during the working week.

What these features have allowed ourselves to do is open up Selecta to you, the fabricator, providing you with an insight in to our window and door system extrusion and distribution operations. We’ve had the satisfaction of explaining how certain areas of the business work, the intrinsic nature of extrusion and product testing, whilst also having the opportunity to introduce you to the strong team that makes Selecta who we are today. The next time you receive a six-metre length of profile, fabricate a beautiful window or French door, you can appreciate it for exactly what it is. To some, it will just be another window or a door. To a few, it will just be a piece of plastic. To Selecta Systems, it will always be that precision engineered product!

In the last issue of Total Fabricator, our ‘behind the scenes’ feature at Selecta Systems looked at the many aspects of marketing support. Continuing with the service and support theme, Technical Manager Cliff Prosser, provides you with an insight in to the realm of technical service and support at Selecta.

Previous behind the scenes features have seen us explain how heavily important we value the personal, flexible and comprehensive service and support side of the business. It’s an area we have always seen as key and it’s no different when it comes to the technical service and support side of the business. We genuinely see our technical department as an extension to your business, providing an array of technical information, assistance, on-site training and guidance alongside our internal and external technical support services to customers.

Co-ordinating and carrying out administrative duties within the technical department is Michele Statham. Her methodical and meticulous approach to the role is key to the smooth operation and success of new customer conversions and set-ups.

Michele is responsible for all stock tooling and special tooling orders for customers, liaising with suppliers and maintaining stock levels. She also works closely with customers and suppliers in organising and ordering the window and door fabrication software package.

One of Michele’s other key responsibilities is managing the technical engineers diaries, of which we have three permanently based on the road, with Kevin Clark covering the north, Steve Belshaw the middle and Kevin Mascall in the south of the UK. Two further internal technical staff can also be called upon to provide support on the road, when and where it may be required. Michele will make certain that all the necessary paperwork is in order, orders are placed and tooling is ready, ensuring for a smooth set-up or conversion to our window and door profile systems.

Our technical engineers provide remote and on-site assistance, guidance and training for all aspects of fabrication and installation. One of the initial key aspects of their role is during the initial set-up and conversion of customers to our profile systems. Factory layout planning, the fitting of machinery tooling, window and door fabrication training, software instructions and all relevant profile system advice is provided from the off, with continued support throughout the customers connection with Selecta.

We have found that our technical engineers build up excellent relationships with our customers base, mainly due to their exceptional knowledge, experience and flexibility of being able to provide a trustworthy and comprehensive technical service and support role. They are seen as the ‘fabricators best buddy’ as they see this is an invaluable service, as and when issues arise, with their extensive fabrication knowledge and ability to assist window and door manufacturing. Couple this with the capability of being able to carry out set-ups and minor machinery repairs, they quickly become the go to guys!

My role, at Selecta, sees myself managing and supervising the technical department, whilst also providing a technical support service to customers, specifiers, homeowners and all those who require specialist technical assistance and guidance. From overseeing new customer conversions and set-ups or advising a homeowner on how to adjust a hinge, to facilitating product testing or advising a confused customers on building regulation changes, every day is different!

The latest and future proposed changes to Document L of the building regulations have seen further investment in our research and development programme. With our existing ADVANCE 70 system meeting the 1.2 U value requirements, we have been looking at both product and glazing capabilities to improve this further. By mid-October, I will have completed a training course to become a WER / U Value approved simulator, thus being able to provide further support to our customer base.

This will aid us further in working towards the proposed 2025 Document L changes as we invest more resources in to developing our window and door solutions. Our company ethos however will remain. Any new developments and improvements shall continue to be fabricator and installer friendly, whilst also being cost effective as is possible for the fabricator and installer.

Over the last couple of years and within these behind-the-scenes features, we’ve mentioned that customer service, support and care remain high on the agenda. Communication is also key. Working with the Marketing Manager, Mark Walker, we have introduced and launched a number of technical information sheets and guidance documents.

We launched two PAS 24 Window and Door Technical Guidance documents, providing customers with a simplified and detailed overview of how to fabricate PAS 24 windows, single leaf and French doors. The simple and effective guides, itemise each piece of hardware, its product code and a visual guide as to where it should be fitted. Feedback from customers has been extremely positive, with the main plus point of being how simplistic and easy to understand the documents were.

This was followed up with the “What the F & L?” Technical Guide, which again was a simplistic overview of the recent changes to building regulations Document F and L. The much talked about trickle vent and U value scenarios and permutations were broken down in to bullet points, thus making the requirements easier to understand.

These three technical guides are just a couple of instances of what we do ‘behind the scenes’ to keep our customers informed and up-to-date with industry requirements and how to comply. To be perfectly honest, it’s very difficult to provide an all-encompassing behind the scenes insight in to our technical support and services. Again, it’s an area that is evolving all the time as we focus on providing a unique, personal and informative service and support package. Technically speaking, it’s all about providing the perfect mix of service, support and communication to strengthen and enhance our relationship with our customers.

What we have learnt over the last few years, is that many events have had, and continue to have, an impact on the way we live and do business. In light of all this, Sales Director Andy Green says it’s “all systems go” at Selecta, explaining the planned systematic approach to future proofing the business and the benefits of using a family and independently owned, UK based PVCu systems company.

There have been plenty of highs and lows within our industry over the last few years and there certainly seems to be further challenges ahead for all, from both a business and consumer point of view. The majority of the industry have experienced increased and record sales, which in-turn has led to many discussions anticipating when the bubble would burst. There is no doubt that the current bout of ‘party’ politics, inflation and soaring costs will have an impact on some within our industry.

So, how well prepared are you, your business and your key suppliers?

For Selecta, the continued success of the last few years have enabled ourselves to invest further within the business and bring forward expansion and improvement plans. The objective being, to provide a strong and solid business for all of our customers and employees for years to come.

We’ve strengthened and further improved our extrusion facility, it’s capabilities and capacities. New and replacement extrusion lines have been installed, improving production quality, facilities and output. New tools and dies have been purchased for key product lines, again improving quality and capabilities. New silos have increased raw material storage and increased end product storage space enables more bar length material stock holding.

We have seen an additional new high speed lamination machine installed, with investment in staff recruitment increasing the number of shifts within the area. This has increased coloured profile stock holdings, as colour continues to grow. A business restructure has seen the lamination area benefitting from increased profile storage space.

Transport and logistics has also seen large investments in its infrastructure. New trucks have been added to our fleet and our recruitment drive has seen us almost double the number of drivers on our books, providing ourselves with far greater flexibility when it comes to delivery options. There are also a further three brand new trucks on order, which with the current situation of delivery timescales, will be arriving in the new year.

Our marketing support has gone from strength-to-strength with an array of new brochures, materials and literature, whilst a new Selecta website is just on the horizon. This will be further supported by a homeowner based website, together with a find a fabricator / installer function to further support our customers and used as a sales generation tool. We also have another innovative feature up our sleeve, again with the aim of supporting and strengthening our relationship with our customer base further.

Connect, our online customer support portal is currently undergoing a re-vamp with some exciting new features being added. This will enable customers to ‘stay connected’ at all times, thus developing our communication channels.

It’s these kind of developments and investments that demonstrate our continued commitment to strengthening our position in the market, whilst providing a range of quality products, service and support package that customers expect. Being family and independently owned has meant that we could re-invest and expand areas within the business quickly – no backwards and forwards with a huge board of directors, shareholders or investors! Being a UK based extrusion and distribution systems company has also taken away the logistics and complexities of dealing outside of the UK! Why am I telling you all of this? Putting it quite simply and as you know, your supply chain is an extension of your business. They fail, you fail. Whether that’s product, service or support related, your supplier is a reflection of you and your business. In good and bad times you need to be able to rely on and trust your suppliers. At Selecta we believe we have future proofed the business, for the benefit of our customers and employees. At Selecta, it’s all systems go…

Irrespective of how good a products qualities are, what has been very evident over the last couple of years is that customer service, support and care remains as important as ever. In this ‘behind the scenes’ feature at Selecta Systems, Marketing Manager Mark Walker, provides you with a candid insight in to the marketing department at the Birmingham based PVCu window and door systems company.

Speaking from a very recent personal experience of purchasing a new car from a dealership. There is nothing more frustrating than buying a quality product, of which I am extremely satisfied with, to be somewhat disappointed in the lack of communication and support that you would truly expect to compliment that purchase. It sours the purchase and relationship.

Although this is different in the terms of it being a B2C experience, rather than B2B, the principles and perception surrounding customer expectations beyond the sale of the product remains. As consumers, many of us will value our involvement with a brand or company purchase, not just solely on the product that we buy, but on the whole customer experience.

At Selecta, we see marketing support as an integral and essential part of that after sales support service. Ensuring that we meet the individual requirements and expectations of a window and door fabrication and/or installation business is key.

Marketing and Customer Support

Heading up Marketing and Customer Support is Donna O’Reilly, who’s bubbly, energetic and friendly approach helps to build strong relationships with potential and existing customers. All online, email and telephone requests from fabricators, installers and homeowners are managed and actioned by Donna, providing a vital service of managing and vetting all sales leads that come in to the business.

Donna also collates a wealth of data to assist in the support of existing and potential business, whilst also providing a range of product and sales reports to the sales director and myself for marketing strategies and plans to be drawn up. These reports provide vital information to aid the continuous development of our marketing support package and services to ensure that we continue to meet our customer’s needs.

We recognise that marketing support goes beyond just the supply of a quality product brochures, information sheets and guides. Combined with the information at hand and the uniqueness and flexibility of the business, it means that the whole marketing support and service package doesn’t stop at just supplying a few brochures!

Creative and Design Service

From a marketing and PR perspective, everything that we create, design and write is done so in-house at Selecta, personally by myself. Whilst external marketing and PR resources work for a variety of businesses, it’s something that Selecta have moved away from for a variety of reasons. The decision was made in early 2014 to build, embrace and develop the skills from within the business. What this has meant is that we have been able to provide a very flexible, unique and personal marketing support service and experience.

For me personally, this means no two days are ever the same! One day I could be designing and creating a brand-new logo for a new customer who has come on board and wants to freshen up their image, then I could then be receiving a design brief from an existing customer who would like graphics designing for his new installation / delivery van. I could then be invited in to a technical meeting where a new fact sheet, guide or booklet is required for customers or a customer may contact me, requiring help with their social media presence, posts and activities!

I’ve worked on an array of customer specific and bespoke projects over the years, like, branded flags, company signs, A boards, posters, vinyl banners, roller banners, videos, stickers, workwear, adverts etc. and even designed wall graphics for customer showrooms! The list of projects is varied, and I’ve often said to customers that if we can do it, we will, but if we can’t, we will tell you… no matter how diverse the request!

The majority of the creative and design work is carried out using the Adobe Creative Suite of software titles. Illustrator, InDesign and Photoshop being the most used software with Premier Pro and After Effects excellent for video productions. This creative and design element of the role is exciting and ticks a big box for some, where they do not have access to these skills within their own business. We’ve opened up the whole customer experience, so that they can utilise our in-house skills and resources to assist their business. We recognise that their success is our success.

The Digital Age

What is now apparent, is that we are now well and truly entrenched in the digital age and these last couple of years has undoubtedly transformed buying habits. Enhanced websites, interactive product designers and ordering systems, lead generation tools, customer support portals and social media presence are now more of a must, than just fancy like-to-have luxuries. Digital marketing and on-line solutions now undeniably form part of any forward-thinking businesses marketing plans and truly within our realms of support. Our assistance already extends to social media, website creation, lead generation and Connect, our customer support portal.

We provide a website package, where the fabricator / installer can have a themed and readymade website where they can add their logo, colour theme, contact details and about us info. This is an excellent quick, simple and effective way of having a brand-new website up and running in next to no time.

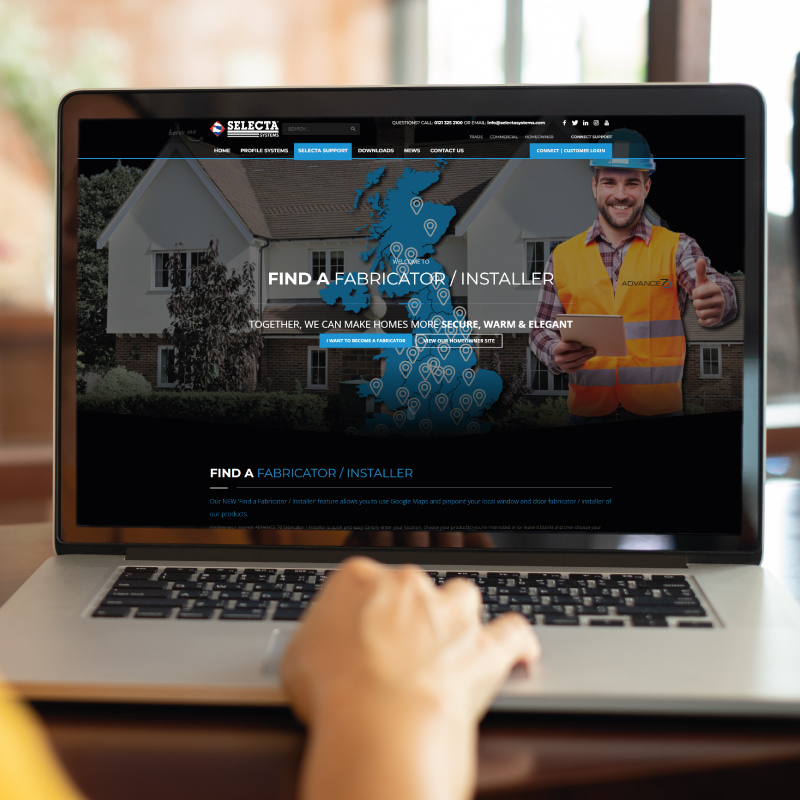

Furthermore, behind the scenes, I have been creating, designing and building two brand new websites. Firstly, a new revamped and fresh Selecta Systems website that is responsive, informative and easy to navigate. This is supported by a completely new homeowners’ website, full of consumer-based information and a Find a Fabricator / Installer function, a simple and effective lead generation tool for our customers.

Our existing site generates a large volume of homeowner leads per week, of which we pass on to our customers. The new websites lead generation capture and reporting functions will provide a far more slicker and sleeker platform for consumers, whilst the planned homeowner inspired digital marketing campaigns will push further traffic to the website. There are also arrangements for further website and on-line add-ons to enhance the homeowner experience and support our customers further, with the intention of generating additional sales leads.

It’s very difficult to provide an all-encompassing behind the scenes insight in to our marketing support and services, as it’s evolving all the time as we focus on providing a unique, personal and extensive marketing service and support package. It’s all about providing the perfect mix to strengthen and enhance the whole customer journey.

Over the last few years, one of the main growth areas in PVCu windows and doors has been the demand for colour. So, in the 3rd part of our ‘behind the scenes’ at Selecta Systems feature, we take a look at the foiling process. Lamination Manager, Dan Coton, takes us in to the colourful world of PVCu profile lamination.

It’s fairly obvious that colour remains high on the homeowner’s agenda as they look to windows and doors that are not only secure and thermally efficient, but that they also complement the style, period and location of their property. This is where colour choice comes in and opens up further opportunities. Consumer demand for coloured PVCu windows and doors has driven innovation in coloured foil options, whilst the development of lamination technology and machinery has seen Selecta invest in this key area.

Production Planning

The Selecta lamination process begins with a daily stock control and production planning meeting between Mark Roberts, Stock Control and Purchasing Manager, and myself. These daily meetings are key to our production planning, as stocks and orders fluctuate on a daily basis. It’s important that we keep an eye on this ever-changing landscape, to ensure that the process is as efficient and effective as is possible, whilst also forward planning any special orders that have been placed in the 24-hour period.

We laminate a range of coloured profiles to stock, not to order, so production planning within the department focuses on a number of factors that determine product runs. Stock levels are an obvious trigger, but it is also important to align this with existing planned production and what special colour orders are currently within the system. It’s easier to slot in a run of the same profile section, but different colour, than to plan it further down the line as this reduces set-up times. We would rather have the machines running consistently and efficiently, rather than stop starting, adding to set-up times, downtime and waste.

Planned runs can be brought forward or pushed back, dependant on the day’s circumstances, needs and demands. That’s why production planning meetings are such an important part of the process, so that these fluctuations can be factored in to daily and weekly plans. Production plans are forever changing and management of this is key.

Production planning also incorporates profile and foil stocking for each production run. Profiles are run to stock in the extrusion and it’s important that the coloured profile substrate is available for picking when required, with foils stocks sufficient to cover. Selecta has invested heavily in increasing the volumes and a range of foil stocks over the last couple of years.

Lamination of PVCu Profiles

A profile section and foil colour requirement is assigned to a particular lamination machine. There are three foiled section possibilities – foil on the bead side face, non-bead side face or both sides of the profile section. A single face profile section set-up on a machine, will very often follow with colour changes throughout the run. For instance, once set-up for a particular section has been completed it is far more efficient to run, let’s say, anthracite grey for the required stock run and then follow this with other stock colours or a special colour, than it is to change over to another section. This will happen even if stock is still available for that profile colour, but we will boost the stock levels further.

Lamination technology has improved considerably over the years with the new machines now all computerised in the respect of primer and adhesive application. The profile section face width is programmed in to the machines computer along with the adhesive weight and spread. The adhesive weight adjusts the thickness of the adhesive, whilst heater settings warm up the profile section and adhesive to make it ‘tackier’ and adjust its adhesiveness.

The set-up of the lamination machine takes on average between 30-45 minutes per side of a profile section. Each forming wheel, guide and cutter is manually adjusted and set to ensure that when the foil is fed on to the profile, each surface, chamfer, sculpture and lip is covered by the foil and formed in to the shape. The coloured foil is oversized to cover the face of the profile section, with the lamination machine cutters trimming the excess foil to the gasket and bead chamber. The correct size of protective tape is put on the feeding wheel, to cover the newly foiled profile section face. Profile section runners are used to fine tune the settings, before the required production quality is achieved and production is approved to continue.

The line speed is set accordingly to the profile section with an average of 15-16 metres per minute. However, this is sometimes determined by pack quantities, as we pack profiles on-line, whereas other lamination houses may pack offline and up line speeds. So, we effectively run, inspect and bag two and half lengths per minute of a one-sided coloured profile section. We see this as a more efficient and effective way of production and it also factors in on-line QC inspection as well as packing.

With each lamination machine approximately 18 metres in length, they require four operatives to be able to run efficiently and effectively. The lamination process starts with the feeder operative wiping the profile down to remove any contaminants, then feeding the profile section along the roller bed in to the machines wheels and guides. The profile section hits the machines priming station first, which contains a chemical cleaner and part adhesive, before heaters dry, warm and prepare the section for the foil. The machine applies the adhesive directly to the foil at the head of the machine, where a foil feeder wheel transfers the foil to the profile section.

The profile section meets with the foil and the wheels, guides and cutters ensure the surface is covered, whilst the machine operator / setter carries out the on-line QC inspection to ensure that there are no imperfections, foreign bodies under the foil and that it has adhered to the profile. Once the protective tape is applied by the machine wheels, the profile is fed on to the roller bed and two packers inspect, bag and lift the finished profile section in to the stillage.

Where two sides are required, the section may be moved on to another machine that is running a similar sized section face or await the second side to be run according to the production plan. The lamination process is repeated for the second side.

The finished coloured profiles are then transferred in to stock and special orders allocated to customers, awaiting picking for their next delivery. Regular external pull tests are carried out, where a weight is applied to the foil to check the adhesion strength of the foil to the profile sections and delamination.

Positive Investments and Environmental Impact

There is an ongoing investment in colour at Selecta with further plant, machinery and infrastructure plans afoot. The new lamination machines upgraded performance capabilities have improved efficiency and output quality, providing greater foil adhesion and a superior foiled finish.

This has also been a big part of our environmental and sustainability programme, with Selecta’s impact on the environment greatly reduced, with all of the solvent-based machines now replaced. The more environmentally friendly hot melt lamination machines have eliminated solvent emissions and improved waste stream management significantly. So, whether it’s standard white or foiled anthracite grey, black, cream or chartwell green, Selecta don’t believe it should be referred to as just a window, door or piece of plastic. To us it is and will continue to be that precision engineered product.

With over 30 years of service with Selecta Systems, Sales Director Andy Green, talks about Selecta turning 40 and how they’ve grown and evolved in to one of the leading systems companies – born in 82, stronger in 22!

Forty years on and Selecta Systems remain independently owned by the same family who started the business way back in 1982. All be it that we are indeed forty years down the line, the strong original business values and ethos remain firmly rooted within the business. Success has been based on a number of simplistic principles and beliefs that have certainly served the business remarkably well over the years.

Flexibility, personal customer care, service and support combined with fabricator friendly profile systems, continue to be key aspects of the Selecta philosophy. These continue to be the core unique features of Selecta, when compared to our competitors of whom many are part of larger groups, investors and shareholders. This systems company uniqueness ensures that Selecta have continued to have a strong, distinctive and individual place within the market when compared with the competition, with a very loyal customer base, backed up by a strong, experienced and longstanding Selecta team – or family as we like to be referred to as!

Today, Selecta are in a very strong position on the back of a record year in 2021, with a solid start to 2022 and year on year monthly figures again on the increase. This is even more rewarding when you consider that we’ve had a couple of years that have been fraught by supply chain issues and rising costs. These last few years have certainly been challenging, yet prosperous for many involved in our industry. However, with consumer demand at levels not seen for many years, it has pushed many of a business to their limits and beyond.

Indeed, Selecta have been caught up in the torment of supply chain issues and our supply from stock business methodology, rather than to order, has been well and truly pushed to its limits. Nevertheless, I believe we came out of this far more quickly and respectfully than the majority in the industry. In-turn this experience has helped to make us stronger, more focused and determined to continue to provide not just a quality range of products, but also a first-class service and personal support package to our customers.

To top it off, we have recently been crowned winners of PVC Company 2021 at the National Fenestration Awards and we are extremely proud to have been recognised by our industry peers for our achievements, especially after what has been a demanding few years.

During all of this time, we have continued to be transparent and upfront with customers on day-to-day operations, stocks, pricing matters and surcharges. We welcome the time when the market steadies, as many of you do, and prices start to fall so we can pass on those savings to our customers.

This exponential growth has seen Selecta hit our projected 5-year growth forecast in just over 12 months! What this has meant to the business, is that we have had to bring forward a majority of our original expansion plans. Prior to the pandemic, we were already on a high and exceeding targets, but no one could have forecast or planned for the boom we have all experienced.

Progress has already been made across the whole of the business and there have already been a number of investments in our infrastructure and logistics, which has included new upgraded plant and machinery, extrusion machines, material storage silos, HGV delivery vehicles, profile foiling machines, staff recruitment and business restructuring. There are further plans afoot for this year and beyond.

From experience and listening to people within the industry, it has also been very clear that customer service, support and care is as important as ever, irrespective of how good a products qualities are. Investment in these areas are key, to not only maintaining existing business, but also attracting future business once the market becomes more competitive. That’s why we have some very exciting plans well underway to stay ‘connected’ with our customers in 2022 and beyond. We are confident in taking our service and support package to a completely new level by developing and enhancing the whole customer experience.

What we have experienced is huge growth across our whole product range, with demand for flush sash windows becoming more popular than ever. There also seems to be a huge resurgence in patio doors as homeowners look at ways to open up their home to the outside. Standard white profiles are still outselling coloured profiles. However, increases in demand for coloured profiles has certainly increased with almost 40% of all profile sales now credited to colour, albeit mostly attributing to Anthracite Grey!

We believe the success over the last few years is down to our original, longstanding values and ethos. The business is constantly developing, but has not forgotten its roots. There is a newfound confidence in the Selecta and Advance 70 brands with existing customers continuing to grow their businesses and larger fabricators making the change. We’re extremely proud to reach the milestone of being able to celebrate our 40th anniversary and welcome you to our stand, K60, at the FIT Show on May 10 – 12th to have a celebratory drink with us. No hard sell. Just a big thank you to everyone who is, may become or has been #partofthefamily

Selecta Systems head to the FIT Show, ready to celebrate their 40th year in business! Sales Director, Andy Green, talks about why it is important to celebrate this momentous milestone and having a presence at FIT Show 2022.

“Reaching forty years in our industry is an excellent achievement in itself, when you consider the number of companies that have been and gone over the years – especially profile systems companies. What is even more unique is that Selecta have continued to remain independently owned by the same family who started the business way back in 1982.”

Andy continues, “There is an enormous sense of pride within the business, in reaching the big 4-0, with success built on a number of simplistic principles and beliefs. Flexibility, personal customer care, service and support combined with fabricator friendly profile systems, continue to be key aspects of the Selecta ethos and values that are firmly rooted within the business. With that in mind, we believe that being at the FIT Show 2022, provides ourselves with the perfect platform to celebrate our 40th anniversary with our customers, industry friends and colleagues.”

Having exhibited at every previous FIT Show and Glassex beforehand, Selecta have been a stalwart in supporting industry specific events. So, what can visitors expect to see from Selecta at this years event?

A relaxed Andy explains, “Exhibitions are generally seen as an opportunity to sell, sell, sell. Everything pointing towards seeing that return on investment by promoting that new product or service. For Selecta, it’s going to be nice to go in to a show where we can be purely there to celebrate and say thank you.”

“Behind the scenes, there have been a number of large investments in our infrastructure and logistics. This has included new upgraded plant and machinery, extrusion machines, material storage silos, HGV delivery vehicles, profile foiling machines, staff recruitment and business restructuring. We also have a host of new customer support mechanisms and initiatives coming your way with two brand new websites, one consumer based to generate sales leads for customers. There’s a big update of our Connect customer support portal, but on the back of two challenging, yet successful years, we’ve seen FIT Show 2022 as the perfect platform to just celebrate and say thank you, with so many people being able to be in one place.”

“FIT Show 2022 will be all about celebrating being 40! It’s an occasion where we can thank everyone who has been part of and continues to be part of the Selecta success story. Our stand will solely be a hospitality area, with a bar serving drinks to everyone who is, may become or has been #partofthefamily and wishes to celebrate our 40th with us! There will be no hard sell and no big product samples on show. We’re there, simply to say thank you and celebrate our success.” says Andy.

“The late-night Wednesday opening, also provides us with the extra opportunity to pop on a bit of music, have a piece of cake and a celebratory drink in a relaxed environment. Over the course of the three days, there will also be an opportunity to win a fantastic prize on our stand too!” Andy concludes, “We’re extremely proud to reach the milestone of being able to celebrate our 40th anniversary and welcome you to our stand, K60, at the FIT Show on May 10 – 12th to have a celebratory drink with us. No hard sell. Just a big thank you to everyone who is, may become or has been #partofthefamily”

In the 2nd part of our ‘behind the scenes’ at Selecta Systems feature, we take a candid look in to window and door product testing. Technical Manager, Cliff Prosser, provides us with an eye-opening account of the rigorous testing processes of achieving PAS 24 certification.

Our first behind the scenes feature spoke about it not just being a window or door and seen as a piece of plastic, but of a precision engineered range of products. What we have is a collection of windows and doors that undergo a series of external tests to ensure that the window and door solutions are compliant to a comprehensive range of standards – thus meeting building regulation requirements.

Window and Door Testing

So, what is PAS 24:2016? Well, PAS 24 is the industry standard for Enhanced Security Performance Requirements for Doorsets and Windows. This is a product assessment specification and primarily referenced in the Building Regulations Approved Document Q. The manufacturer, or systems company in this case, submit a range of window or doors to a UK Accreditation Service (UKAS) accredited test house for testing to PAS 24 and the relevant ‘fit for purpose’ standards.

Rigorous testing methods for forcing entry are carried out to ensure that there can be no failure of components that make up that window or door. Testing also includes BS 6375 consisting of weathertightness, operational performance and strength, ensuring that the windows and doors serve their two main purposes of protecting the property from unwelcome visitors and keeping inclement weather at bay. In this feature we’ll concentrate on PAS 24 product testing.

Prior to any fabrication of test windows and doors, a number of research and development meetings are held with hardware, component and accessory suppliers to ensure that the appropriate hardware is used, and in certain cases profile specific, to ensure maximum performance.

Test windows are generally made up of the largest side hung, next to the largest top hung over a fixed window, whereas French doors are made to the largest configuration, thus also covering single leaf doors as a worst-case scenario. Our patio and EASi-FOLD doors were again fabricated to the anticipated largest pane sizes to cover a number of configurations. These configurations and sizes provide the fabricator / installer with the opportunity of offering a vast range of multi-light window and door options, where PAS 24 is a requirement.

Once set up in a test rig, mechanical load tests are carried out on each locking point of our test window. A load of 3.0kN, which is approximately 300kg, is progressively applied from the inside at each locking and hinge point, whilst an external 1.0kN parallel load is applied at the same time for a total of 10 seconds. This can be applied two or three times, horizontally and vertically at each locking and hinge point, dependant on the locking and hinge points on the top hung and side hung windows.

For our test doors, a load of 4.5kN, is progressively applied with an external 1.5kN parallel load applied, following a similar process to windows and all locking and hinge points. An infill mechanical test is carried out on the four corners of the fixed window and on any slave glazed infills, where 2.0kN is applied for 10 seconds.

If you’ve ever had the opportunity to view these tests, you really do appreciate the quite brutal forces that are applied, which intend to replicate an intruder attack using nail bars.

Up to five, three minute manipulation attack tests are then carried out, where a craft knife is used to cut through the PVCu, in an attempt to expose the hinges, locks and cams. A choice of nail bars, flat head screwdrivers or paint scrapers are used to try to break or release the locking points, again simulating a manual attack. A further three minute manual attack is also made with a craft knife in an attempt to cut through the bead and free up the glass. Watching the severe ruthlessness of these attacks makes you appreciate the qualities and strength of PVCu windows and doors when the appropriate hardware, furniture and fixings are used.

When testing our doors, they were also subjected to soft body and hard body impact tests. The objective of the soft body test is to assess the door assembly’s resistance to impacts using a soft body – a pendulum fall of a leather spherical bag of approximately 350mm diameter filled with dry sand to a total mass of 30kg.Three impacts are conducted at three points, which simulates a body charge or an intruder kicking the door.

The hard body impact is to assess the hardware, infill and its retention system to a series of hard body impacts by the pendulum fall of a cylindrical steel block having a mass of 50kg. Three impacts are made on the lock cylinder when fitted, at each corner of the leaf, on the door leaf at each locking point, on the door leaf at each hinge point, on a midrail, if fitted, at the centre of non-glass infill mediums and at each corner of the infill. Should panels be present, each corner and the centre of panels are also impacted. The whole purpose of this test is to simulate an unwanted visitor attacking with a sledgehammer.

When it comes to our doors PAS 24 security hardware and cylinder tests the objective of this test is to assess the door furniture, hardware and cylinder resistance to a 10 minute overall manual attack. The total time of each attack shall not exceed 3 minutes and consists of several activities where there is an attempt to remove, dislodge or otherwise gain access to the cylinder by attacking any item protecting the cylinder, attempting to break or defeat the cylinder by applying a twisting or bending force orif access to the internal workings of the hardware, cylinder or lock is gained, then attempt to defeat the lock and gain access by operating any accessible mechanism. An attempt is also made to screw a self-cutting traction screw into any part of the exposed cylinder and then try to break and defect the cylinder by employing force to the screw.

A standard cylinder can be bumped, snapped or drilled in a matter of seconds and after all the brutality of all the locking and hinge point attacks, it becomes quite futile when access can be gained easily and very quickly when using an inadequate cylinder. Every component, whether its on a door or a window, has to do the job and serve the purpose it there to do – prevent intrusion.

Let’s just say the PAS 24 mechanical and physical attacks leave windows and doors in a sorry state, but with the right hardware they will hold firm against the ruthless nature of the attacks. That’s why our research and development process is so important. From profile design and indicative testing through to collaboration with the supply team, to ensure the right components are used, and where required, profile specific. I must emphasise that fixings are so very important and imperative to a good performing window or door when under attack! There’s no point in having the best hardware and components if you’re not using the correct fixings to ensure that it cannot be manipulated or eased out of place when under attack. That’s why we here at Selecta don’t believe it should be referred to as just a window, door or piece of plastic. To Selecta it will always be that precision engineered product.

Selecta Systems Marketing Manager, Mark Walker, talks about the use of digital marketing and on-line platforms as a way of being customer ready; in the event of consumer demand starting to cool and when the market starts to become more ‘competitive’.

After two years of consumer demand at levels not seen for many years, we ultimately see ourselves heading in to 2022 and beyond speculating how this and next year will possibly pan out. Taking in to consideration that the last couple of years has been fraught by supply chain issues and rising costs, it has remained a challenging, yet prosperous time for many involved in our industry.

Whilst this demand has been welcomed, investment in marketing and support may have been put on the back burner. I’ve always said it’s very easy to fall into the trap that when business is good, some may think you don’t need to invest in your marketing and customer support. I believe that it is probably the perfect time to invest for the future good of the business and customers. It’s certainly far tougher and more costly to market and build your business and brand, to generate new and maintain existing business, in bad times than it is in good times. So how well prepared are we all if and when consumer demand does start to cool?

What has been made very clear is that customer service, support and care is as important as ever, irrespective of how good a products qualities are. Investment in these areas are key to not only maintaining existing business, but also attracting future business once the market becomes more competitive.

What is now apparent, is that we are now well and truly entrenched in the digital age and these last couple of years has undoubtedly transformed buying habits. Enhanced websites, interactive product designers and ordering systems, lead generation tools, customer support portals and social media presence are now more of a must, than just fancy like-to-have luxuries. Digital marketing and on-line solutions should undeniably form part of any forward-thinking businesses marketing plans. There is now a more distinct prerequisite to focus on the whole customer experience and support mechanisms, to be able to fully ‘connect’ with a customers journey.

A key digital marketing strategy and plan is currently underway to take Selecta marketing and customer support to a whole new level. Firstly, a new revamped and fresh Selecta Systems website is on its way, being responsive, informative and easy to navigate. This will be supported by a completely new homeowners website, full of consumer based information and a Find a Fabricator / Installer function, a simple and effective lead generation tool for our customers.

On average 20-25 homeowner leads per week are currently captured on our existing Selecta website, of which are passed on to customers. The new websites lead generation capture and reporting functions will provide a far more slicker and sleeker platform for consumers, whilst the planned homeowner inspired digital marketing campaigns will push further traffic to the website. There are also arrangements for further website and on-line add-ons to enhance the homeowner experience and support our customers further, with the intention of generating additional sales leads.

There are also plans in place to ‘stay connected’ with the Selecta customer base, with our on-line customer support portal, Connect, which is accessible through our website undergoing a major upgrade with a host of new features that will further support, expand and improve the customer experience. At Selecta, our focus has always been on providing a personal and extensive customer service and support package, whilst being able to go above and beyond competitors capabilities. By being independently and family owned, the Selecta structure has always allowed for greater flexibility than the majority of other systems companies. Combining this with the advancements in digital technology and on-line support, we are confident of providing the perfect mix to support and enhance the whole customer journey.

- 1

- 2